Welding and riveting

In SOME the mechanical unions with welds and / or rivets allow us to manufacture pieces composed of several components, metal assemblies and light structures for different industrial sectors.

At SOME we use welding and rivet technologies depending on the needs of the project, and in both cases we have extensive experience and capabilities.

On the one hand, in the industrial area we have a specific machinery park for welders and rivets for second operations.

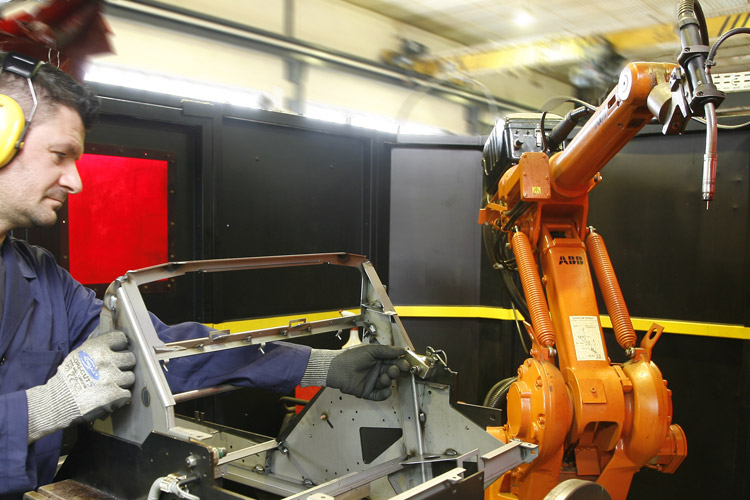

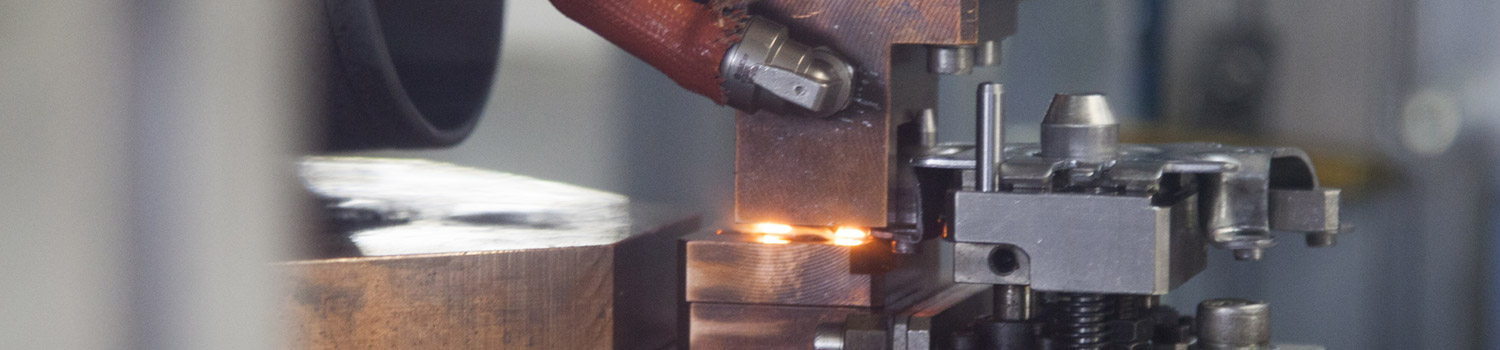

We have several centers for riveting and welding robotized by points and wire type TIG-MIG, as well as several manual welding centers that allow assembling several components.

On the one hand, at SOME Industrial we have a specific welding and riveting machinery park consisting of several centers for riveting and welding robotized by points and by wire type TIG-MIG, as well as various manual welding centers. One system or another is used depending on the requirements of the piece / client and the size of the manufacturing lot.

On the other hand, at SOME Automotive we have automatic assembly stations designed specifically for each project. Due to the high demands of quality and precision demanded, the automated stations combine different processes of mechanical joints in fast cycles and incorporate three-dimensional verifications in line by scanner and artificial vision, so that we achieve complete solutions, highly productive and with maximum reliability and precision with our mechanical joints.

| Automated welding by points | Double workstation |

| Manual welding by points | 45 KVA |

| Manual welding by points | 140 KVA |

| Automated welding by thread | Double workstation |

| Manual welding by points | 180 KVA. Medium frequency machine |

| Automatic assembly stations | Welding and riveting |

| 100% automated verifications | Scanner and artificial vision |