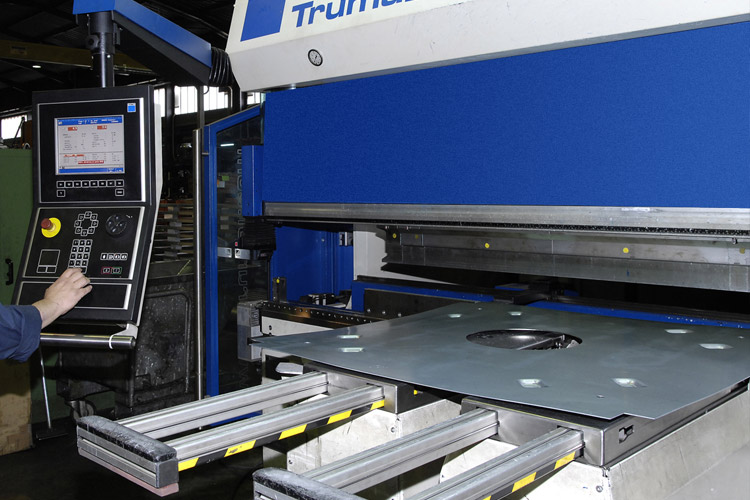

CNC bending

The CNC bending process, also known as sheet metal bending, is the operation that allows folding the metal sheet with great accuracy to obtain the required part geometry.

The CNC bending technique requires a professional team with expert knowledge of the CNC folding machines. The use of the machinery is complex, since the operation allows to create a bending of sheet very useful for the hardness and the resistance of the metallic structure.

The plate folding process is done with a press that has a simple punch and matrix, which allow a low initial investment and very competitive prices.

This machinery exerts the necessary force on the part, producing a plastic deformation on an axis, which will conform the piece according to the client's requirements. Depending on the angle or shape that is desired for sheet metal folding, there are different dies for its elaboration.

Among the best known, on the one hand, there is the bottom fold, known as folded V. And, on the other, the partial fold, called also folded edge, for deformations with a variety of angles.

In SOME we have CNC folding machines that offer high flexibility and quality, which allow you to fold the sheet with great accuracy. By means of the CNC technology, it guarantees an excellent repetitividad of the process and agility in the preparation of the machine.

| Bending machines (CNC) | Up to 3000 mm. |