Progressive metal stamping

At SOME we are specialists in progressive metal stamping for parts with high technical requirements in the sheet metal forming process.

The progressive metal stamping consists of a mechanical operation that can include different operations such as perforation, wedging and other deformations for the transformation of the metal part with the same matrix.

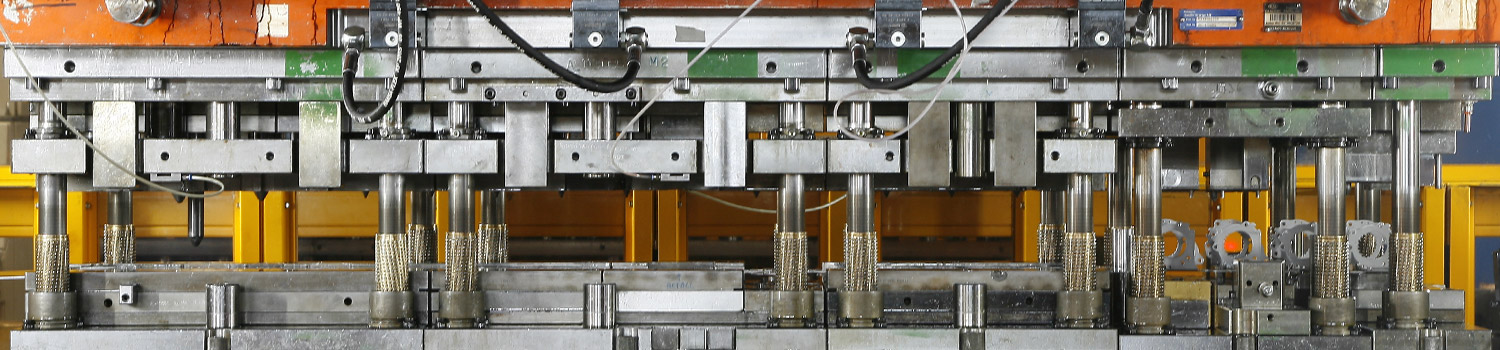

he progressive metallic stamping is achieved with the progressive stamping die, which has several cutting or deformation operations, through which the metal sheet passes as it advances through the die. The progressive stamping dies allow a large number of bending, cutting and drilling operations to be carried out in a single matrix.

The progressive stamping presses incorporate a continuous feeding system by means of a reel, which allows a high level of automation and, therefore, efficiency and adjustment of production costs.

SOME, a company with international expansion, is aimed at the industrial and automotive sector. Therefore we have more than 25 presses from 15 Tn to 500 Tn of power. These machines for the stamping of metals provide us with a great capacity and versatility to apply the most efficient and productive processes according to the requirements of each project in the sheet metal transformation process.

Our machinery park for progressive metal stamping includes high speed presses. From BIHLER type presses, modern Servo Presses, to automatic presses of small, medium and large tonnage.

| BIHLER presses | from 15 to 25 Tn |

| High-speed automatic presses | from 20 Tn |

| Medium and large tonnage automatic presses | from 250 to 500 Tn |

| Medium tonnage automatic SERVO presses | from 400 Tn |

| Small tonnage automatic presses | from 40 to 160 Tn |

| Small tonnage mechanical presses | from 125 125 Tn |