SOME innovation: the 3D optical scanner

SOME has just incorporated 3D optical scanner technology to guarantee the dimensional quallity of its products.

SOME has always been concerned to be at the forefront and work with the best available technologies, as in this case with the 3D optical scanner.

At SOME we want to offer the best service and the best quality, without this implying an increase in the cost of the product.

Since 1973, we have evolved and created an industrial group that is a leader as TIER2, in the automotive sector, and a reference supplier in all types of high precision metal parts and assemblies for numerous industrial sectors.

In our 21,000 m2 of production facilities, we deal with solvency and reliability all types of projects from materials such as iron, stainless steel, aluminum or copper, among others.

The fact of working with highly demanding clients, who are leaders in their sectors, forces us to continuously optimize our processes.

For this reason, we incorporate the 3D optical scanner that, by means of a superficial sweep of points in the 3 dimensions of the space, allows us to measure with high precision in complex geometries, analyze them at a high speed and make agile decisions about compliance with the specifications of our products.

What is the innovation?

Despite being high technology, the friendly environment of the equipment and the customized peripherals facilitate that our operators can operate with it without the need of having advanced technical knowledge.

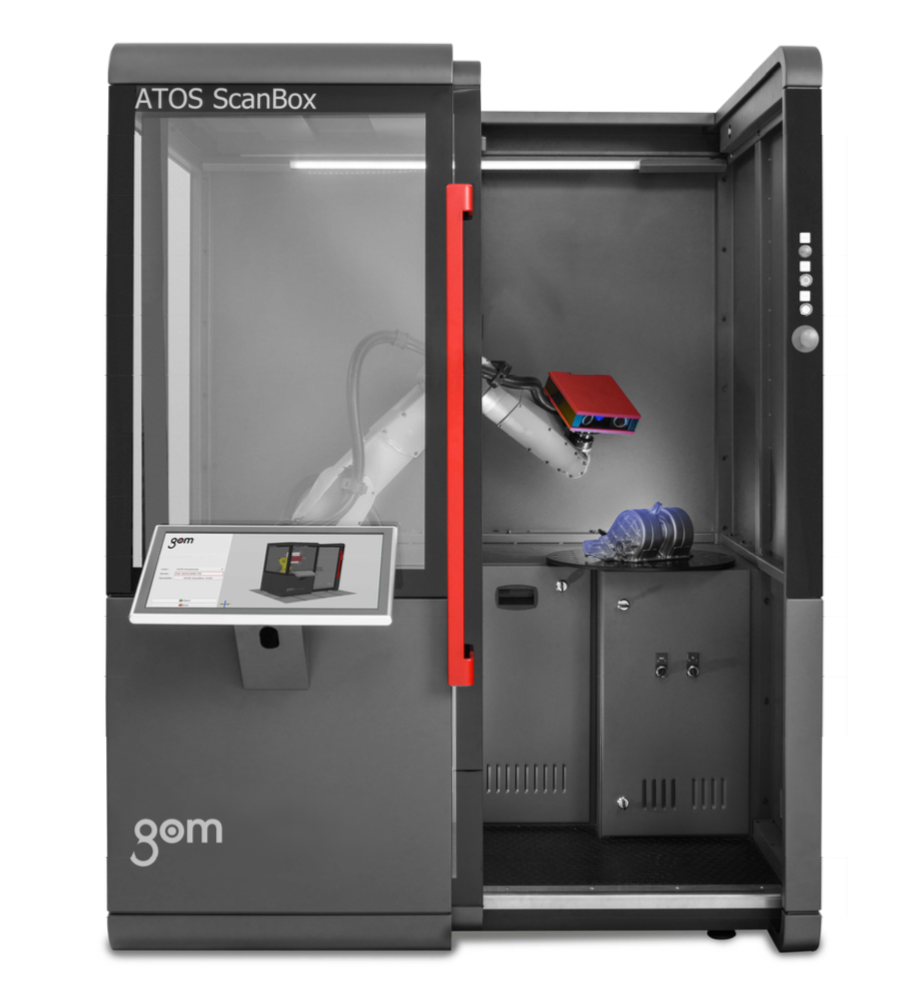

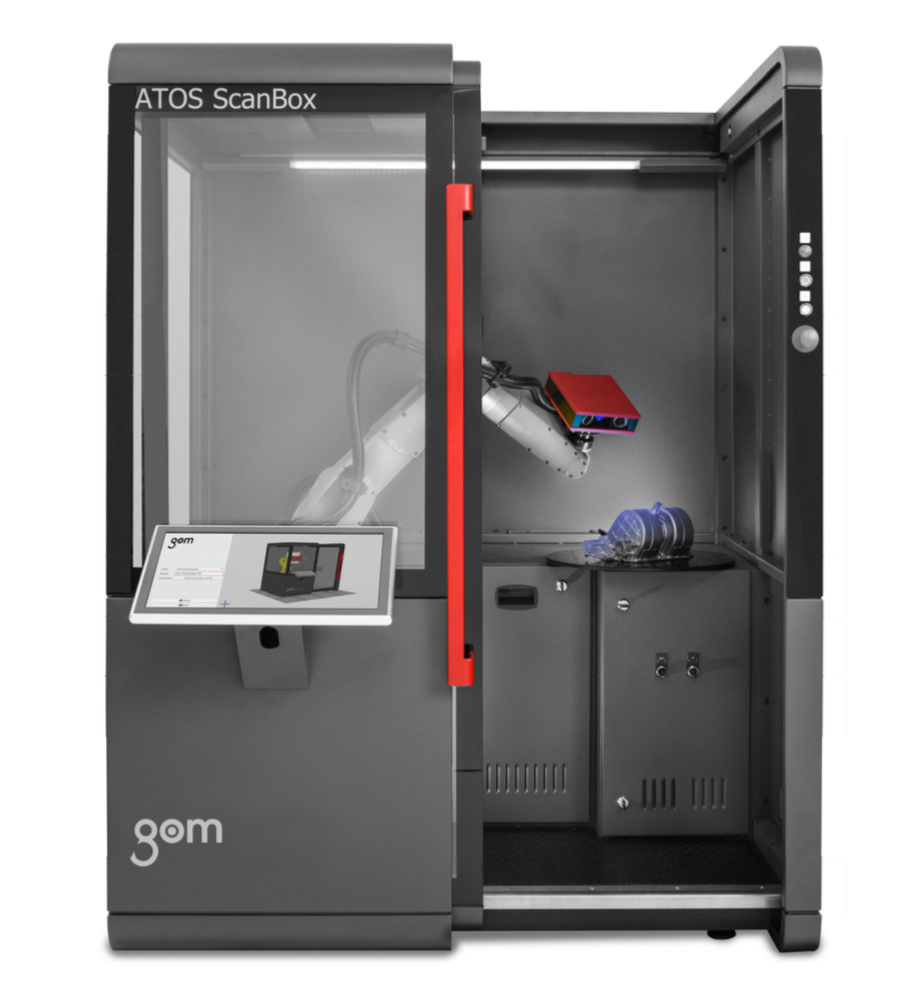

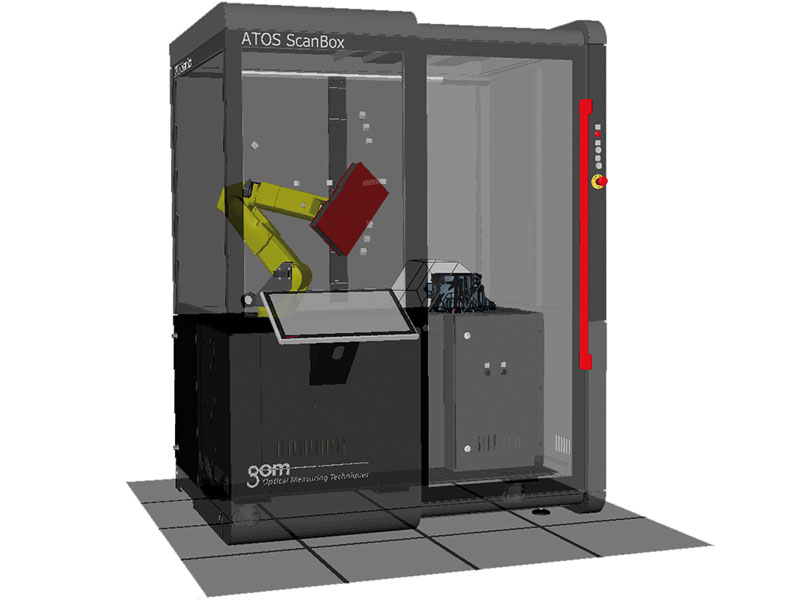

It is used above all for the automated measurement and inspection of small and medium-sized parts and components. The ATOS ScanBox 4105 offers new possibilities for efficient automation for smaller measurement volumes.

The measuring cell is suitable for objects up to 500 mm in size and 100 kg in weight.

Another innovation is that while mechanical measuring machines capture data in a linear or dotted fashion, optical 3D coordinate measurement systems provide full-field deviations of real 3D coordinates and CAD data.

3D scanner applications

Possible applications include quality control related to production in ceramic cores, castings and plastic.

General technical details of the SOME 3D laser optical scanner

- BRAND: GOM

- MODEL: SCANBOX ATOS 4105 / ESCANER ÒPTIC 3D CORE 300

- SOFTWARE: ATOS PROFESSIONAL VMR

- RESOLUTION: 2 CAMEREA 5 Mega Pixel GigE CCD, 2448x2050 pixels

- MEASUREMENT AREA: 300x230 mm

- COMPONENTS:

- ROBOTIC ARM FANUC 6 AXES

- ROTATING PLATE Ø300 mm

- MAXIMUM MEASUREMENT SAMPLE: Ø500mm x 500mm height,

- MAXIMUM WEIGHT: SAMPLE: 100 Kg

Virtual measurement room (VIRTUAL MEASURING ROOM)

The Virtual Measuring Room (VMR) is the central control station and the measurement planning software for all the elements of the ATOS ScanBox 4105.

The VMR eliminates the requirement for specific robot programming skills. The robot can be completely controlled through a simple and secure software interface. As we have previously commented, it does not need specialized operators, which is a great advantage for any company.

The VMR allows programming, complete inspection and reports to be prepared in advance without blocking the system. This great advantage allows for short downtimes and fast response times. Minimize production stops.

KIOSK INTERFACE

Kiosk Interface is a machine interface that allows a simplified interaction with the measuring machine.

Automatically handles the complete workflow of measurement and inspection.As human interaction is reduced, high accuracy and data quality is guaranteed, and measurement, data and operating system parameters are protected.

Upcoming international events with the participation of SOME:

This year we will participate in:

- Midest / Lyon: https://www.midest.com/fr

- Hannover: https://www.hannovermesse.de/home

WE WAIT FOR YOU!

News

-

SOME, manufacturers of metal parts and components for 3D printers

20/03/2019We work closely with our customers in the areas of engineering and prototyping to achieve optimum product design and manufacturing process.

-

Laser cutting machine, 50 years of evolution

14/03/2019The laser cutting technique is one of the most widely used operations for cutting sheet metal parts in the industrial and automotive sector.

-

SOME improves the energy efficiency of its plant in Sant Quirze de Besora

13/03/2019This will allow to achieve a saving in electricity consumption of 384,8MWh/year.

-

What is industrial punching and what is its process?

05/03/2019At SOME Stamping Solutions we have the latest technology to be able to develop the industrial punching process -

SOME Stamping Solutions at Hannover Messe

27/02/2019SOME Stamping Solutions will participate as an exhibitor in Hannover Messe, Germany, one of the most recognized industrial fairs in the world.

-

Glossary of industry terms (I)

26/02/2019From SOME Stamping Solutions we have elaborated the following glossary of industry terms with the aim of collecting frequently used words.

-

Metal joining techniques: welds and rivets

20/02/2019SOME Stamping Solutions is a leading supplier of all types of metal parts and assemblies. We manufacture welding and riveting processes with specialized machinery.

-

Differences between cold metal stamping and hot metal stamping

13/02/2019There are two types of stampings, cold stamping and hot stamping, depending on the temperature applied to the material to be deformed.

-

What is the laser cutting technique for?

05/02/2019The laser cutting technique, one of the most used processes in the industrial sector.

-

SOME innovation: the 3D optical scanner

25/01/2019SOME has just incorporated 3D optical scanner technology to guarantee the dimensional quallity of its products.