Optimization in the design of an integral production process.

In the manufacturing of a complex frame, the engineering services of SOME Industrial achieved a practical, reliable and productive solution, optimizing each of the phases of the entire production process and its logistics.

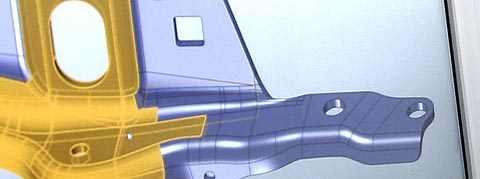

This was the manufacturing and supply of a frame for a manufacturer of arcade machines. From the blueprints of the customer, the complexity of the project was detected, which included up to 17 components in the structure. SOME Industrial designed a practical and reliable solution of the entire production flow, including laser cutting and bending processes to manufacture the components, the assembly of all parts, painting, packing and transportation logistics.

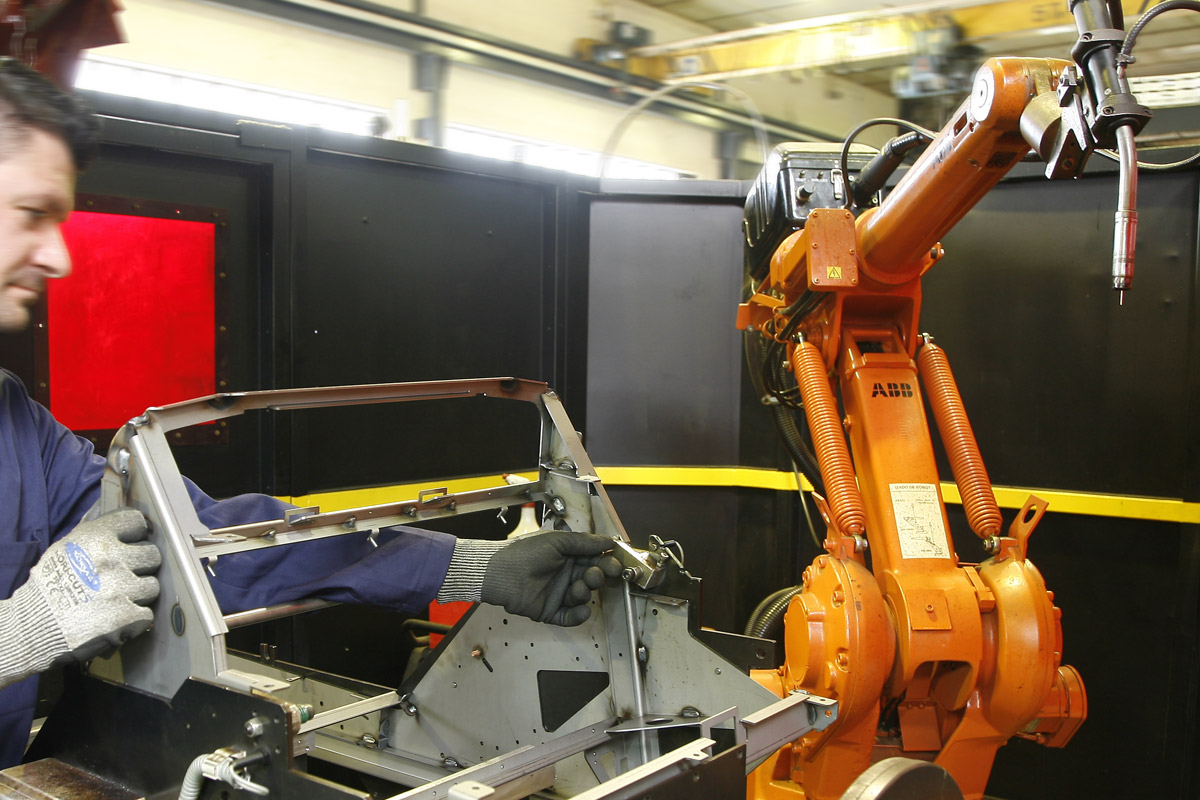

The critical assembly process was optimized through a welding robot by threads with two turning tables so that the robot could access all points. At the same time the welding tools are used to calibrate and verify the components, so that the robot does not start unless the components do not have the corresponding calibrations.

Through the Kaizen tools and the adequate flow to the Just in Time system, the supply in line of the components manufactured with Soft Tooling was set up with the robot for maximum efficiency.

The packaging of the finished parts was redesigned in order to avoid carrying air. A new design of the box with a perfect fit and the protection of the parts reduced the size and allowed to re-stack the pallets, with a significant reduction of the costs of logistics.

The joined result was a practical, reliable, efficient and productive solution, which improved the internal manufacturing process of the customer and its affordability, achieving complete satisfaction.

Related divisions

Related services

News

-

SOME, manufacturers of metal parts and components for 3D printers

20/03/2019We work closely with our customers in the areas of engineering and prototyping to achieve optimum product design and manufacturing process.

-

Laser cutting machine, 50 years of evolution

14/03/2019The laser cutting technique is one of the most widely used operations for cutting sheet metal parts in the industrial and automotive sector.

-

SOME improves the energy efficiency of its plant in Sant Quirze de Besora

13/03/2019This will allow to achieve a saving in electricity consumption of 384,8MWh/year.

-

What is industrial punching and what is its process?

05/03/2019At SOME Stamping Solutions we have the latest technology to be able to develop the industrial punching process -

SOME Stamping Solutions at Hannover Messe

27/02/2019SOME Stamping Solutions will participate as an exhibitor in Hannover Messe, Germany, one of the most recognized industrial fairs in the world.

-

Glossary of industry terms (I)

26/02/2019From SOME Stamping Solutions we have elaborated the following glossary of industry terms with the aim of collecting frequently used words.

-

Metal joining techniques: welds and rivets

20/02/2019SOME Stamping Solutions is a leading supplier of all types of metal parts and assemblies. We manufacture welding and riveting processes with specialized machinery.

-

Differences between cold metal stamping and hot metal stamping

13/02/2019There are two types of stampings, cold stamping and hot stamping, depending on the temperature applied to the material to be deformed.

-

What is the laser cutting technique for?

05/02/2019The laser cutting technique, one of the most used processes in the industrial sector.

-

SOME innovation: the 3D optical scanner

25/01/2019SOME has just incorporated 3D optical scanner technology to guarantee the dimensional quallity of its products.