Product engineering value: PT-COVER Case

Thanks to the Engineering and Design services of SOME Automotive, the design of the part was optimized, achieving significant savings in the cost of the product and an increase of the productivity of the production lines of the customer and SOME.

One of the biggest TIER1 global companies of the automotive industry, provider of all type of products for important brands in the safety, prevention and electronics industries, among other, trusted SOME with the evaluation of possible cost improvements in one of their safety components.

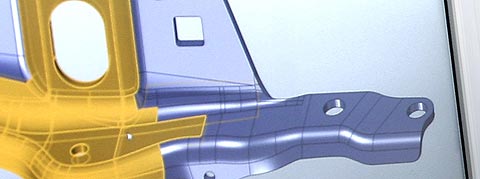

The part was the cover of a pretensioning element of a safety belt with an attachment system with six axes that cross this part with the corresponding anchoring structure, riveted on the production line on both ends in order to attach the part firmly to the structure of the mechanism.

SOME‘s engineering services redesigned the product by creating extruded holes that only needed riveting on one end, eliminating the cost of the axes. The attachment was much stronger, and therefore the number of attachment points were reduced from 6 to 5 and 4.

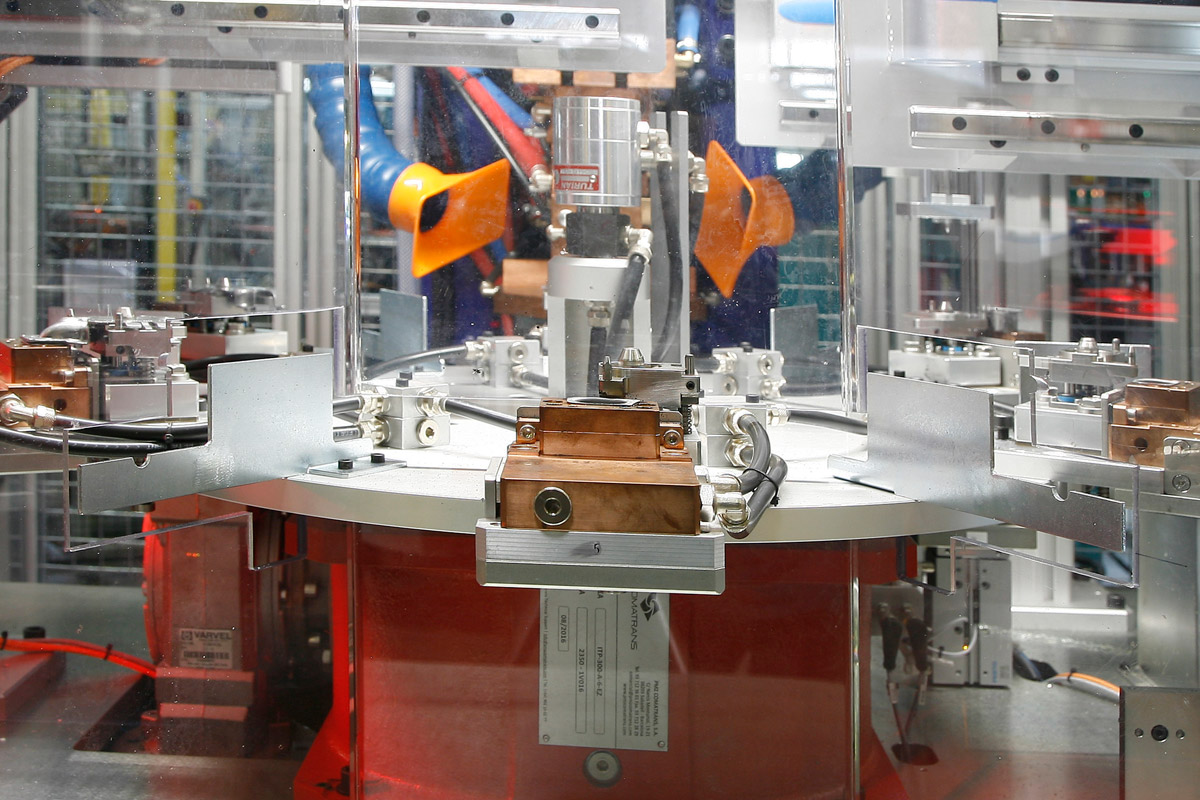

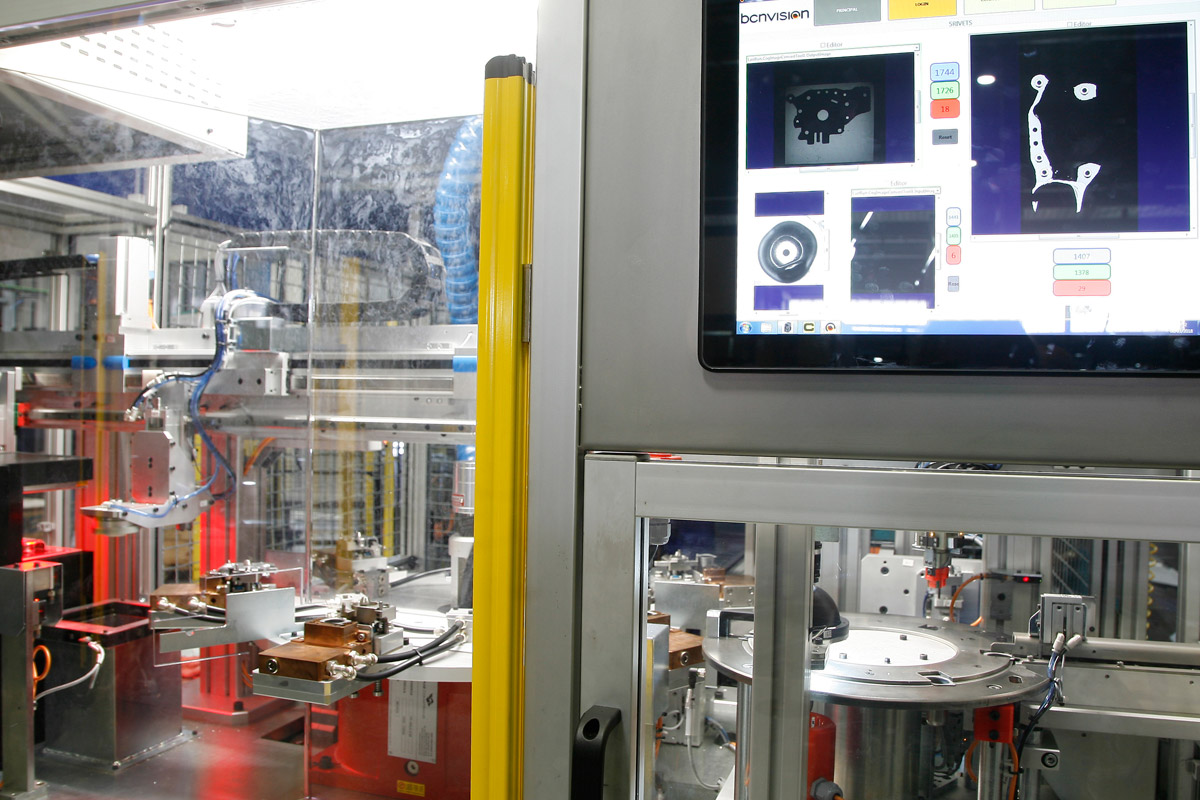

The solution created by SOME meant a reduction of 20% in the cost of the part of 20% and an increase of the productivity in the production process. The component became a standard with application in many other products of the customer, multiplying the demand for the product ten times, which required investing in 3 new automated production stations.

Gallery photos

Related divisions

Related services

News

-

SOME, manufacturers of metal parts and components for 3D printers

20/03/2019We work closely with our customers in the areas of engineering and prototyping to achieve optimum product design and manufacturing process.

-

Laser cutting machine, 50 years of evolution

14/03/2019The laser cutting technique is one of the most widely used operations for cutting sheet metal parts in the industrial and automotive sector.

-

SOME improves the energy efficiency of its plant in Sant Quirze de Besora

13/03/2019This will allow to achieve a saving in electricity consumption of 384,8MWh/year.

-

What is industrial punching and what is its process?

05/03/2019At SOME Stamping Solutions we have the latest technology to be able to develop the industrial punching process -

SOME Stamping Solutions at Hannover Messe

27/02/2019SOME Stamping Solutions will participate as an exhibitor in Hannover Messe, Germany, one of the most recognized industrial fairs in the world.

-

Glossary of industry terms (I)

26/02/2019From SOME Stamping Solutions we have elaborated the following glossary of industry terms with the aim of collecting frequently used words.

-

Metal joining techniques: welds and rivets

20/02/2019SOME Stamping Solutions is a leading supplier of all types of metal parts and assemblies. We manufacture welding and riveting processes with specialized machinery.

-

Differences between cold metal stamping and hot metal stamping

13/02/2019There are two types of stampings, cold stamping and hot stamping, depending on the temperature applied to the material to be deformed.

-

What is the laser cutting technique for?

05/02/2019The laser cutting technique, one of the most used processes in the industrial sector.

-

SOME innovation: the 3D optical scanner

25/01/2019SOME has just incorporated 3D optical scanner technology to guarantee the dimensional quallity of its products.