SOME is consolidated as a solvent “technology partner” for its customers

The continuous addition of modern technologies in SOME, together with the consistent application of reliable solutions, has allowed us to create the necessary trust from our customers to participate in co-investments in the production processes.

Since 2010, with the investment of a first customer in riveting machinery, which increased the production capacity that was necessary, new relationships were initiated in the processes that SOME was developing for the customer‘s project.

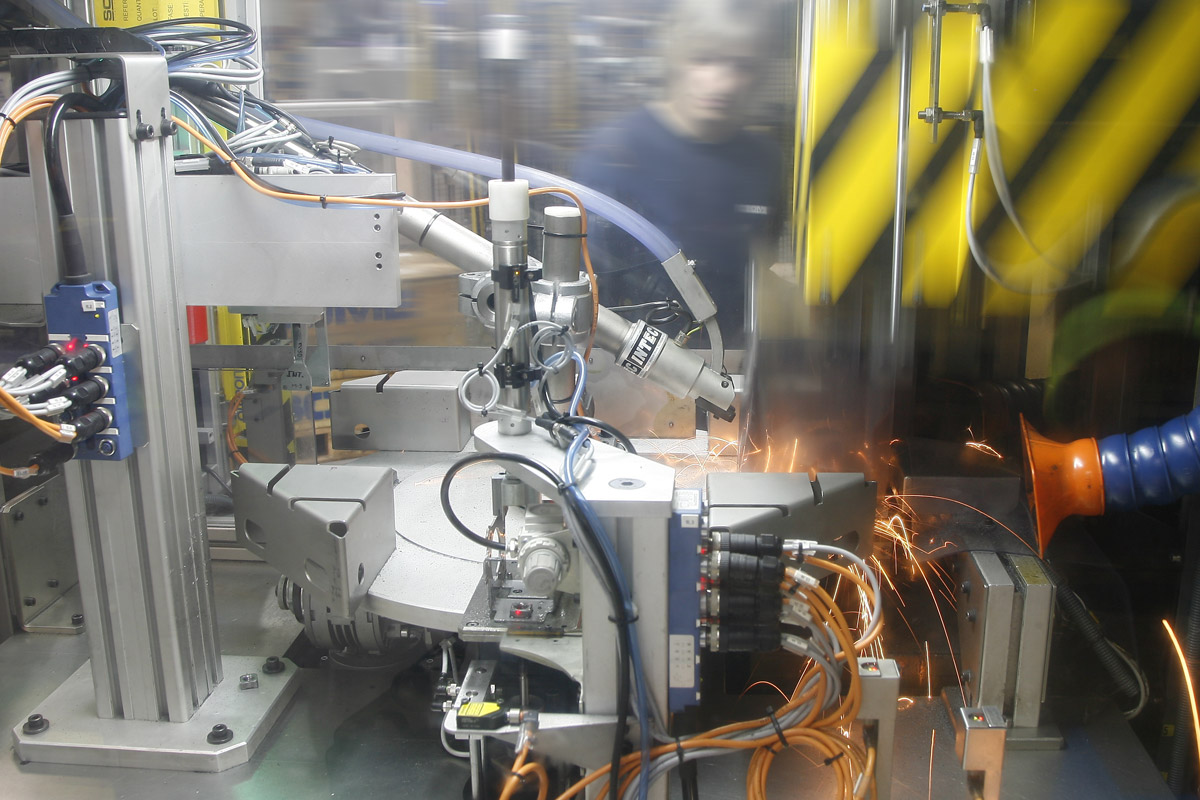

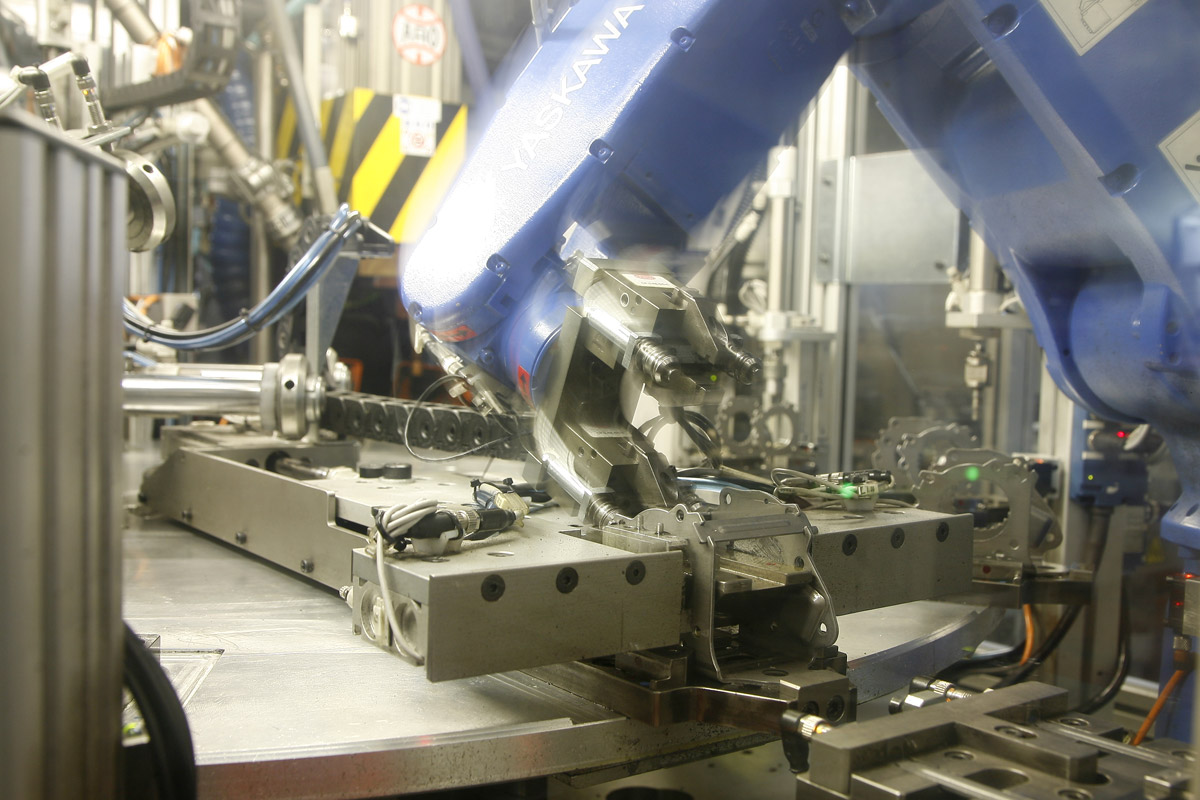

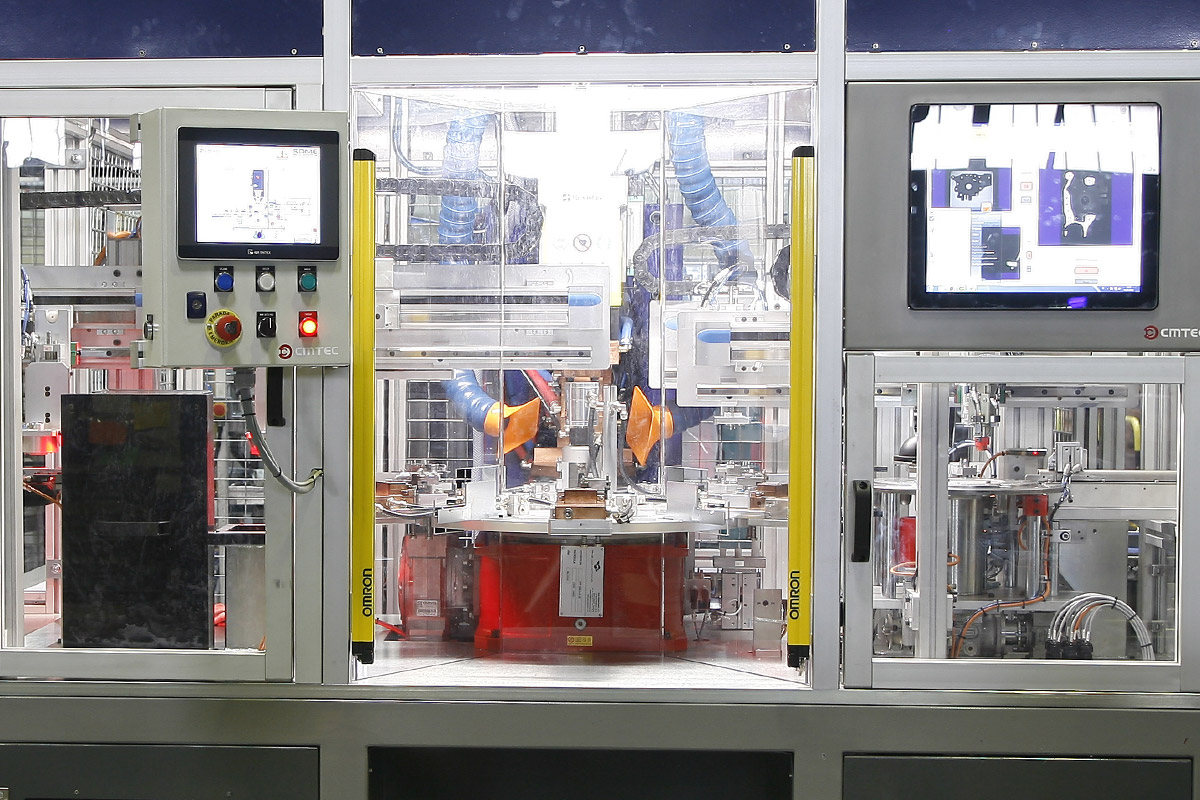

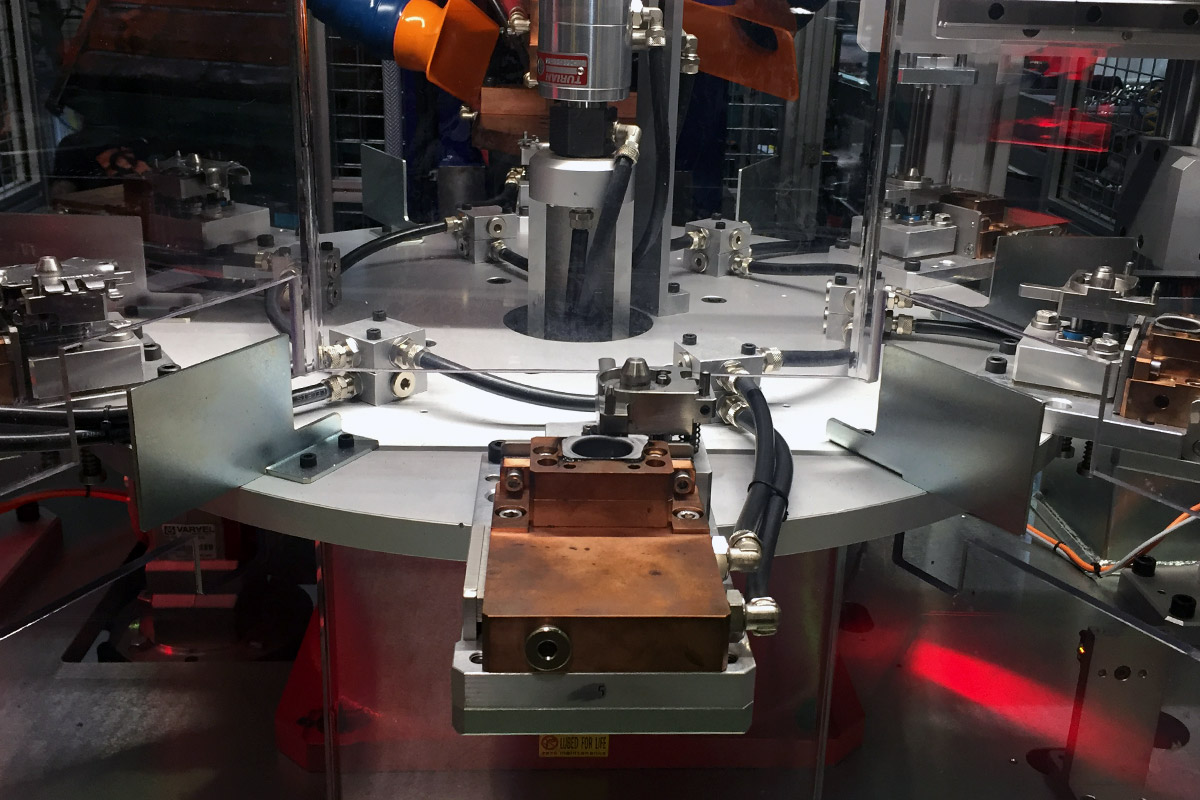

In this way, in 2015 a new section was "professionalized" with the first large project in an automated station, followed by 2 more in 2016, 3 in 2017 and 3 more in 2018. This new area of SOME is comprised of automated stations with a high technological level, advanced robotics and artificial vision systems for in-line verification of 100% of the production. They are fast machines with 3-4 second cycles with single control which multiply the production capacity for the manufacture of 7-8 millions of parts/year.

According to the requirements of each customer, the process engineering services of SOME create and design the processes and controls that each automated station will perform, which will be later developed and manufactured by specialized and completely reliable engineering.

In line with the trends that SOME identified in the market, this new area of strong growth was established, and SOME provides experience and advances engineering in order to satisfy, with complete reliability and quality, the strict requirements in accuracy and capacities of the customers of the automotive industry.

Gallery photos

Related divisions

News

-

SOME, manufacturers of metal parts and components for 3D printers

20/03/2019We work closely with our customers in the areas of engineering and prototyping to achieve optimum product design and manufacturing process.

-

Laser cutting machine, 50 years of evolution

14/03/2019The laser cutting technique is one of the most widely used operations for cutting sheet metal parts in the industrial and automotive sector.

-

SOME improves the energy efficiency of its plant in Sant Quirze de Besora

13/03/2019This will allow to achieve a saving in electricity consumption of 384,8MWh/year.

-

What is industrial punching and what is its process?

05/03/2019At SOME Stamping Solutions we have the latest technology to be able to develop the industrial punching process -

SOME Stamping Solutions at Hannover Messe

27/02/2019SOME Stamping Solutions will participate as an exhibitor in Hannover Messe, Germany, one of the most recognized industrial fairs in the world.

-

Glossary of industry terms (I)

26/02/2019From SOME Stamping Solutions we have elaborated the following glossary of industry terms with the aim of collecting frequently used words.

-

Metal joining techniques: welds and rivets

20/02/2019SOME Stamping Solutions is a leading supplier of all types of metal parts and assemblies. We manufacture welding and riveting processes with specialized machinery.

-

Differences between cold metal stamping and hot metal stamping

13/02/2019There are two types of stampings, cold stamping and hot stamping, depending on the temperature applied to the material to be deformed.

-

What is the laser cutting technique for?

05/02/2019The laser cutting technique, one of the most used processes in the industrial sector.

-

SOME innovation: the 3D optical scanner

25/01/2019SOME has just incorporated 3D optical scanner technology to guarantee the dimensional quallity of its products.