Welcome to SOME

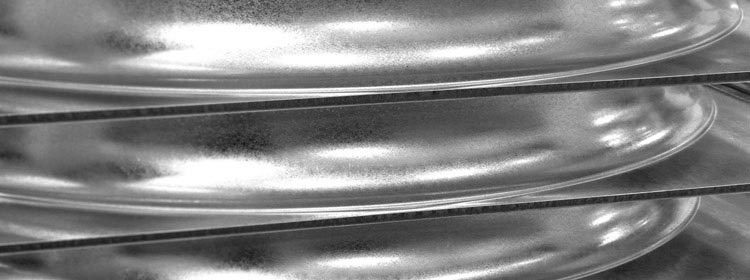

We are an industrial group expert in sheet metal transformation processes, capable of providing solutions both to the automotive industry and other industries.

+20.000 m2

Facilities

+300

Professionals

+180 mill.

Parts/Year

27 Countries

Presence

Business Units

With the purpose of providing the most adequate solutions to each type of customer, SOME has two independent business units in order to meet specific needs, both in the Automotive industry and other industries, which require more flexibility.

What we do

We are experts in the transformation of sheet metal thanks to our wide range of cold forming processes, the integration of advanced technologies and the provision of value added services for complete custom solutions.

Quality and environment

Part of SOME’s DNA is ensuring quality and environmental management, which has made us preferential providers to leading companies in their markets.