What is the difference between laser cutting and punching?

Laser cutting or punching? The process of handling sheet metal forming can become very complex. Especially, if you are not used to working in the industrial or automotive sector.

From SOME, a specialist sheet metal projects company, we want to give you the keys so that you can always know the differences between laser cutting and CNC punching.

Laser cut

Laser cutting technology is the technique used to engrave or cut metal sheets or materials that allow the construction of pieces of different geometries such as stainless steel or aluminum sheets. It is characterized because its energy source is a laser that concentrates light on the work surface to make the cut.

This technique allows you to develop complicated contours in the parts and ensure the customer a great precision in the shaping of your piece of sheet metal. It requires a specialized and very technical machinery, but the results are as expected for the client. It allows to offer quick and agile responses to the needs of the user.

At SOME we make the laser cutting process of different materials according to the needs of our customers:

- Laser cutting stainless steel

- Laser cutting iron sheet

- Aluminum laser cutting

- Laser cutting sheet metal

Consult more information about the laser cutting process

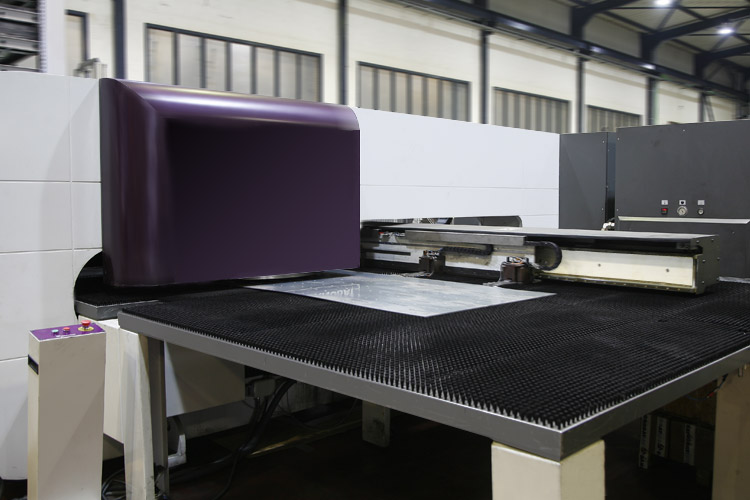

CNC punching

Punching is the operation that makes holes in the sheet or metal sheet. The CNC punching machine has a series of specialized tools to perform this technique: the punch, the gripper and the matrix.

At SOME we have an expert team to perform the punching technique. Learn more about CNC punching.

With international expansion, at SOME we have more than 30 years of experience in the industrial and automotive sector.

Contact us now for more information.!

News

-

SOME, manufacturers of metal parts and components for 3D printers

20/03/2019We work closely with our customers in the areas of engineering and prototyping to achieve optimum product design and manufacturing process.

-

Laser cutting machine, 50 years of evolution

14/03/2019The laser cutting technique is one of the most widely used operations for cutting sheet metal parts in the industrial and automotive sector.

-

SOME improves the energy efficiency of its plant in Sant Quirze de Besora

13/03/2019This will allow to achieve a saving in electricity consumption of 384,8MWh/year.

-

What is industrial punching and what is its process?

05/03/2019At SOME Stamping Solutions we have the latest technology to be able to develop the industrial punching process -

SOME Stamping Solutions at Hannover Messe

27/02/2019SOME Stamping Solutions will participate as an exhibitor in Hannover Messe, Germany, one of the most recognized industrial fairs in the world.

-

Glossary of industry terms (I)

26/02/2019From SOME Stamping Solutions we have elaborated the following glossary of industry terms with the aim of collecting frequently used words.

-

Metal joining techniques: welds and rivets

20/02/2019SOME Stamping Solutions is a leading supplier of all types of metal parts and assemblies. We manufacture welding and riveting processes with specialized machinery.

-

Differences between cold metal stamping and hot metal stamping

13/02/2019There are two types of stampings, cold stamping and hot stamping, depending on the temperature applied to the material to be deformed.

-

What is the laser cutting technique for?

05/02/2019The laser cutting technique, one of the most used processes in the industrial sector.

-

SOME innovation: the 3D optical scanner

25/01/2019SOME has just incorporated 3D optical scanner technology to guarantee the dimensional quallity of its products.